greenchemistry

Green Chemistry focuses on : • Reduction, recycling and/or eliminating toxic substances • Finding creative, alternative routes to minimize impact on the environment • More eco-friendly green alternative toconventional chemistry practices • Provides sustainable development, sustainable business and sustainable living practices

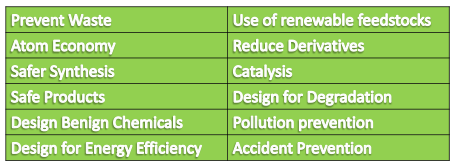

Twelve Principles of Green Chemistry

- Prevent Waste :

- Synthesis only targeted product with minimum or no by products/waste

- If waste is produced , it involves cost and time to treat and safely dispose it, as a result production cost increases

- Atom Economy: Synthetic methods should be

- designed to maximize the incorporation of all materials used into the final product

- The chemical processes should have maximum product yield

- Atom economy can be calculated using the relation

- % Atom Economy = (FW of atoms utilized/FW of all reactants) X 100

Atom Economy in a Substitution Reaction - moderate Atom Economy in Elimination Reactions - low Atom Economy in Addition Reactions -100% Atom Economy in Rearrangement Reactions -100%

For a green synthesis atom economy must be maximum (100%)

- Safer Synthesis:

- The synthetic processes should be

- designed so as to minimize or prevent the production of hazardous substances

- Necessary safety precautions have to be taken while processing to protect human health and environment

- eg: Polyurethane is manufactured conventionally using and alcohol. However, isocyanate is produced using phosgene, a toxic gas

- The alternative method by green synthesis of polyurethane eliminates the use of phosgene and uses CO2

- Safe Products : Chemical products should be designed

- to preserve efficacy of function while reducing toxicity

- Products should not have any side effects on the people using it and on the environment

- It is envisaged to produce the chemical products specially those being used in cosmetics, pharmaceuticals, etc.

- Design Benign Chemicals :

- Use safer solvents and reaction conditions

- Avoid using solvents, separation agents, or other auxiliary chemicals

- If these chemicals are necessary, use innocuous chemicals

- Chemical syntheses are assisted by solvent medium:

- recommended to use alternative solvents , greener in nature such as aqueous medium, liquid carbon-dioxide, ionic liquids(N-alkyl pyridinium cation with BF4-), or solvent free systems

- Avoid harmful solvents like chloroform, pyridine which are known to cause health hazard, are carcinogenic to human beings and animals or cause severe damage to environment

- Design for Energy efficiency :

Chemical processes are to be designed in such a way that they are less energy intensive

- reactions occurring at mild conditions

- require less time to complete

For this purpose it is worthwhile to utilize

- Bio-catalyst, homogeneous and heterogeneous catalyst which reduces the energy of activation

- Modern techniques such as solvent free synthesis, supercritical fluid systems, microwave irradiation, and ultrasound

- Use of renewable feedstock :

- Raw material or feedstock used as starting material should be renewable rather than depleting wherever technically and economically possible

- Use of renewable feedstock such as biomass and agricultural wastes are strongly recommended rather than using non-renewable resources such as coal, petroleum-based raw materials, etc.

- Reduce Derivatives:

- Avoid unnecessary derivatization

- temporary modification should be avoided whenever possible as they generate waste

- the atom efficiency is reduced as the protective group is not incorporated in the final product e.g: blocking group, protection/ deprotection

- Catalysis:

- Use catalytic reactions, as catalysts

- Speed up the reaction can be recycled and are highly selective

- less energy consumption during reaction

- obtaining high yield of product of high purity

Unlike stiochiometric reactions which are energy intensive require excessive reagents

- Design for Degradation :

- Design chemicals and products to degrade after use to innocuous substances after use so that they do not accumulate in the environment

- Especially applicable to:

- insecticides

- pesticides

- polymers which tend to persist in the environment and are known to cause bioaccumulations

- Pollution Prevention :

- Real-time analysis (quality control)

- Continuously monitor and control the formation of hazardous substances

- Any unreacted reactant can be recycled in order to minimize the use of chemicals

- Accident Prevention :

- Minimize the potential for accidents

- Chemicals chosen for processes should be such which minimise accidents in the form of fires, explosions, and toxic releases to the environment

- Manufacturing plants should be well equipped with safety mechanisms

- The Bhopal gas tragedy is one of the worst industrial disasters

Green chemistry is a set of principles which emphasises on

- environmentally benign chemical synthesis with a view to devise pathways for the prevention of pollution.

- bringing a paradigm shift in chemical processing to achieve sustainable development.